|

|

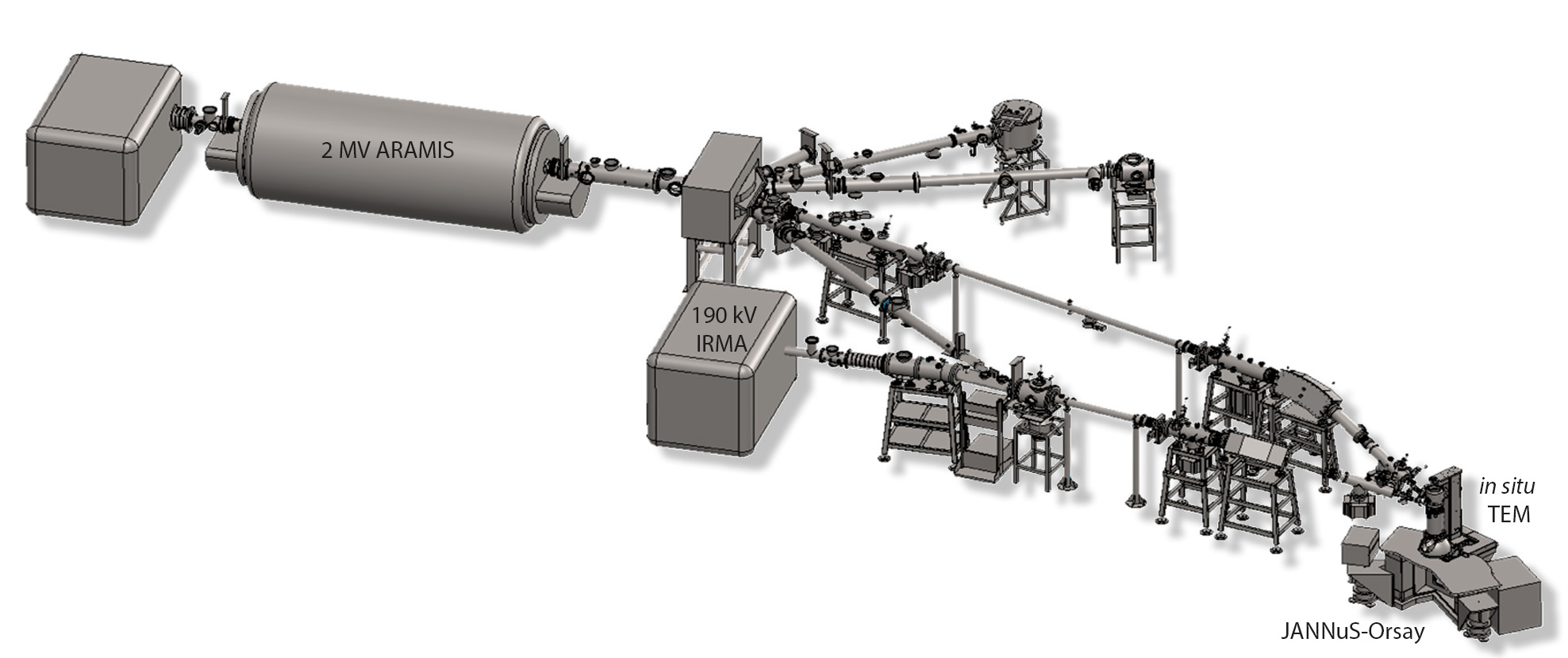

ARAMIS is an ion accelerator with a nominal voltage of 2 MV, which was developed in the laboratory. It has a positive source (Penning type) and a negative source (Middleton), associated with its two modes of operation, Van de Graaff and Tandem, respectively.

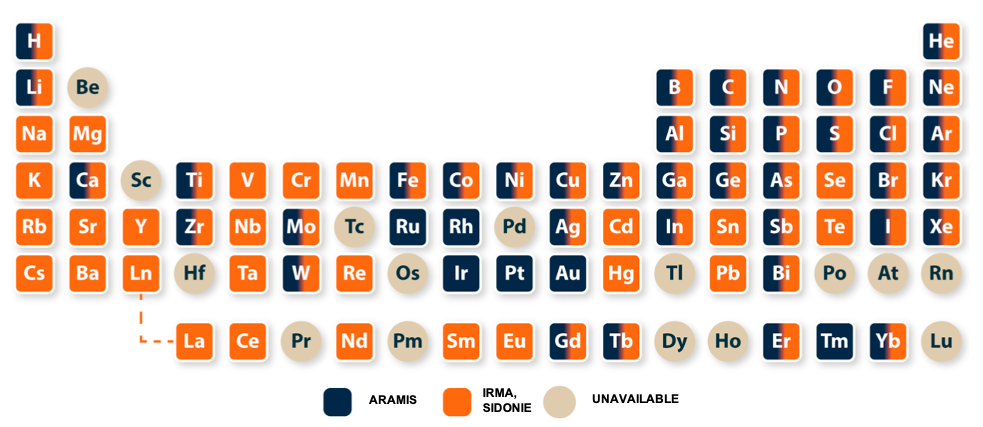

Equipped with various sample holders, the ARAMIS ion accelerator allows a wide range of ion irradiation and material synthesis studies to be carried out. The 35 chemical elements available make it possible to carry out “self-irradiation” damage studies (without chemical pollution), with fluxes between 1×109 and 1×1012 at/(s*cm2), and masses ranging from 1 to 197 UMA , at energies between 100 keV and 11 MeV. This range of ion beams also allows wide possibilities for doping materials up to a depth of about ten µm. Equipped with a 4-axis goniometer, SDD and germanium detectors, ion beam analysis techniques (such as RBS, RBS/C, PIXE, PIGE, ERDA) allow the elementary quantification of materials, with discrimination in depth, as well as the study of defects in crystalline materials. The coupling with the IRMA ion implanter allows the in situ analysis of irradiation effects in a material. The coupling of ARAMIS with the TEM allows the in situ study at the nanometric scale of the evolution of the modifications induced by the ions in a material.

Reference articles :

• Progress report on ARAMIS, the 2 MV tandem at Orsay, H. Bernas, J. Chaumont, E. Cottereau, G. Moroy, C. Clerc, O. Kaïtasov, D. Ledu, M. Salomé, Nucl. Instr. and Meth. B 62 (1992) 416-420 doi

• ARAMIS : an ambidextrous 2 MV accelerator for IBA and MeV implantation, E. Cottereau, J. Camplan, J. Chaumont, R. Meunier, H. Bernas, Nucl. Instr. and Meth. B 45 (1990) 293-295 doi

• ARAMIS : an accelerator for research on astrophysics, microanalysis and implantation in solids, E. Cottereau, J. Camplan, J. Chaumont, R. Meunier, Materials Science and Engineering B 2 (1989) 217-221 doi

For any request: mosaic@ijclab.in2p3.fr